If you have ever stayed at Saruya, you may have noticed that you’re sleeping very comfortably. The reason may lie in the bedding used.

Saruya’s futon covers, pillowcases, and bath towels are made of linen. (*in twin rooms.) Linen is a material that is well suited to bedding due to its high breathability and sweat absorbency, but it is rarely used in hotels due to its cost and tendency to wrinkle. Then, why does Saruya use it?

These linens are produced by Tenjin Factory (hereinafter referred to as “Tenjin”), a textile manufacturer that has been operating for three generations in Fujiyoshida City. Originally, Saruya’s owner Tsuyoshi Yagi worked with Tenjin to design brochures and other communication material for them and around 2017, when they started a new series of linen bedding, Tenjin offered to have Saruya customers experience the comfort of their bedding and Saruya didn’t hesitate.

Linen is a key material for comfortable sleep

Interestingly, the term “linen” is also used to refer to fabrics in general, such as “bed linen” and “table linen”. It is true that fabrics used in hotels can be made of various materials like cotton, polyester, silk, etc., but they are collectively called “linen”. This is because historically, linen has been the most commonly used fabric. The term “linen” was first used to refer to fabrics, and later, when cotton became available for mass production and synthetic fibers were introduced, the variety of fabrics became more diverse. That’s how long linen has been around and how it has become a part of our daily lives. Nowadays, linen may be thought of as a fashionable summer fabric or a luxurious material, but when you pay closer attention, there are many aspects that make it suitable for bedding and towels.

Linen fibers are hollow and contain a lot of air. This air helps regulate the temperature, making it feel cooler in summer and warmer in winter. Linen is said to be three times more absorbent than cotton, so it not only absorbs water and sweat well, but also dries quickly. It is also strong enough to last for a hundred years if used carefully, and the more you use it, the more the texture will improve.

The reason why you don’t see much linen in ordinary hotels is because they are difficult to mass-produce, costly, shrink easily, and wrinkle easily. At Saruya, a small inn with less than 10 rooms, staff members wash sheets and towels in the washing machine and hang them out to dry in the courtyard. Furthermore, they don’t iron the linens which gives a more natural feeling to the fabric.

Timeless craftsmanship using shuttle looms

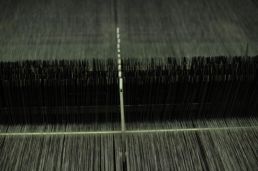

Tenjin’s factory is located about a ten minutes walk from Saruya. When I arrived at the factory, I could hear the rhythmic sound of clanking coming from inside the building. There are many other textile factories in Fujiyoshida, which is one of the leading textile production areas in Japan, and it is quite common to hear the sound of looms, but compared to them, the rhythm at Tenjin seems slower. The reason for this is the speed of the looms used.

A loom is a machine that combines warp and weft threads to produce cloth. You may have seen people sitting in front of a machine and weaving cloth with a wooden bar, but except for a few traditional crafts, most of the mass-production is automated. The loom used at Tenjin is a “shuttle loom”, an old-fashioned type of loom that is no longer manufactured. The speed at which this machine operates is about 100 revolutions per minute, which is a very low speed. Rapier looms, which replaced the shuttle looms, are capable of about 300 revolutions per minute, and current jet looms are going over 1,000 rpm. And at that speed the sound is a roar, which is far less enjoyable than the slow clanking of the shuttle loom.

When Tenjin started to produce linen bedding, they decided to introduce old shuttle looms. The machine had already been discontinued, but they acquired theirs from a factory in Fujiyoshida City that had gone out of business. The slower the speed, the lower the manufacturing efficiency and the higher the cost. However, a fast loom inevitably pulls the yarns too hard, making the finished cloth hard and flat, and losing the unique texture of the material. 100rpm is a deliberately slow speed that creates more room between the threads and enhances the soft texture and breathability of linen.

The yarn used at Tenjin for bedding is from Europe. Flax is grown all over the world, but the best varieties for bedding, towels, and other items that emphasize texture are grown in the cold regions north of Europe, mainly in France and Belgium. Bed linens made with material of such high quality are not only comfortable to the touch, but also affect the quality of sleep. Some people even say that they sleep better after switching to linen pajamas.

A facet of linen that applies to Saruya: "If used carefully, it can last a 100 years"

When Saruya started using Tenjin’s futon covers and bath towels, they were very well received by their customers. Some of them not only want to buy the products, but also want to visit the factory and learn more about the textile industry in Fujiyoshida. This comes as a great satisfaction to Saruya who values their relationship with the local industry. And neither Tenjin nor Saruya can actually remember who originally asked for or offered the bedding to the other as the relationship was so natural between them.

We carefully use products made with care.

Like a shuttle loom, we slowly weave our daily lives.

We cherish things that are timeless and universal.

The values that Saruya unconsciously cherished are embodied in Tenjin’s linens.

Today, the sight of white sheets and towels fluttering under the blue sky has become one of the scenes that symbolize Saruya. Just like linens that can last for 100 years if used carefully, hotels can last for 100 or 200 years if they are passed down with care, and I am looking at the white sheets swaying in the courtyard today thinking of what Saruya might then be.

Written by:

Yumi Igarashi

I live in Yamanashi Prefecture. I worked for a resort hotel management company for 10 years, and after visiting Karuizawa, Ishigakijima, and Fukushima, I've been working as a freelance hotel management advisor and writer for several years. I don't remember how I got involved with Saruya, but I've been coming and going, helping out with work or just visiting.